(April 2025)

The German standards “DIN 11853-1 /-2 /-3, stainless steel components for hygienic applications in the food industry” have been revised

This affects stainless steel components for hygienic applications in the food industry, consisting of the following parts:

Part 1: Pipe connections

Part 2: Flange connections

Part 3: Clamp connections

Application of the standards

“This document specifies the dimensions, design and materials of tube connections with O-ring for hygienic applications in the food industry for butt welding to tubes with dimensions in accordance with DIN 11866 and DIN EN 10357, series A and series C. The grooved union nut is specified in DIN 11851.”

The following changes to the DIN 11853-1 /-2 /-3 standards are described (please refer to the individual standards for details):

- Scope of application restricted to the food industry

- Section “Symbols and abbreviations” added and symbols changed

- “Ordering data” section added, details of the designations moved there

- Specification of the nominal diameter of series B and series C adjusted

- Inner diameter of pipe and flange ends summarized and tolerance adjusted

- Length lKa added and adjusted

- Tolerances of the outer diameters of nozzles with wall thickness < 2 mm have been reduced

- Tightening torques corrected

- 1.4435 added as material

- FFKM added as seal material

- PTFE added as seal material

- Hygiene classes H3 and HE3 added

- Acceptance criteria for visual inspection adjusted

- Labeling adapted

- Section “Assembly” added

- Annex “Seals made of elastomers” adapted and status set to normative

- Annex “PTFE gaskets” added

- Appendix “Material comparison” deleted

One change is that ordering examples are shown for the first time. In this way, the standardization committee wishes to clarify the use of the existing, changed and newly added designations.

For the time being, LINNEMANN will retain the previously used designations until the new spellings have become established. However, thanks to our knowledge from the committee's work, we can answer inquiries with both the previous and the new designations.

You will find the articles of these standards in the flip catalog in chapters B8, B9 and B10.

Example of an aseptic / hygienic clamp connection

(April 2025)

The German standards “DIN 11864-1 /-3, Stainless steel components for aseptic applications in the chemical and pharmaceutical industry” have been revised

This affects stainless steel components for aseptic applications in the chemical and pharmaceutical industries, consisting of the following parts:

Part 1: Pipe connections

Part 2: Flange connections

Part 3: Clamp connections

Application of the standards

“This document specifies the dimensions, design and materials of tube connections with O-ring for aseptic applications in the chemical and pharmaceutical industry for butt welding to tubes with dimensions according to DIN 11866. The grooved union nut is specified in DIN 11851.”

The following changes to the DIN 11864-1 /-3 standards are described (please refer to the individual standards for details):

- Section “Symbols and abbreviations” added and symbols changed

- Section “Ordering data” added, details of the designations moved there

- Specification of the nominal diameter of series B and series C adapted

- Inner diameter of the pipe or flange ends summarized and tolerance adjusted

- Length lKa added and adjusted

- Tolerances of the outer diameters of nozzles with wall thickness < 2 mm have been reduced

- Tightening torques added

- Tolerances for gaskets changed

- FFKM added as seal material

- PTFE added as seal material

- Marking adapted

- Requirement for clamp connection in assembled state added

- Section “Assembly” added

- Annex “Seals made of elastomers” expanded and given normative status

- Appendix “PTFE gaskets” added

- Appendix “Material comparison” deleted

One change is that ordering examples are shown for the first time. In this way, the standardization committee wishes to clarify the use of the existing, changed and newly added designations.

For the time being, LINNEMANN will retain the previously used designations until the new spellings have become established. However, thanks to our knowledge from the committee's work, we can answer inquiries with both the previous and the new designations.

You will find the articles of these standards in the flip catalog in chapters B8, B9 and B10.

Example of an aseptic / hygienic pipe connection

(October 2021)

General information for all future or revised standards.

- All versions of all parts available to order must be listed in the standard.

- Inch measurements are no longer permitted. Only metric size designations in mm are allowed.

- The size designations are based exclusively on the corresponding pipe dimensions "pipe outer diameter x wall thickness"; DN sizes are no longer specified. As a result, the previous size designation based only on the outer diameter of the pipe or weld end is no longer valid. If DN is still specified despite this, it only serves as information, e.g. for calculations in accordance with the European Pressure Equipment Directive.

- New options exist for the design of surfaces, welds, etc. These are identified through letters. It should be noted that the same letters are used several times. They have different meanings in each standard.

- The existing acceptance criteria are specified more precisely.

- The number of possible certificates is extended.

(October 2021)

2021: Publication DIN EN 10374: 2021-10

In October 2021, a European standard "Welded fittings for the food and chemical industries" was published for the first time. It replaces the corresponding German standard DIN 11852.

DIN EN 10374 standardizes welded fittings for pipes DIN EN 10357

+ Series A (DIN, old DIN 11850),

+ Series C (ASME) and

+ Series D (SMS).

Series B (ISO) pipe dimensions pursuant to DIN 11866 do not exist in DIN EN 10374 as in DIN EN 10357 for pipes

The requirements for welded fittings are described in Chapter 7 of DIN EN 10374. Chapter 7.2 “Manufacturing process” is of particular relevance:

welded fittings can be manufactured from welded pipes DIN EN 10357 or DIN EN 10217-7 (old DIN 7457), seamless pipes DIN EN 10216-5 (old DIN 17458/17459) and from sheets and strips as per EN 10088-2 or EN 10028-7.

In accordance with DIN EN 10374, welded fittings may also be manufactured from non-heat-treated pipe (BC) (identifier "u"), which was not permitted by DIN 11852. Welded fittings made of heat-treated pipe (CC) or non-heat-treated pipe with subsequent heat treatment are less susceptible to corrosion (identifier "a").

The weld seams can remain untreated (identifier "w") or be retreated after welding (identifier "f"), whereby the weld seams must be flush with the base material and the acceptance criteria must be met.

Note on risk of confusion:

In DIN 11865, long tees with an untreated weld seam are marked with the letter "u".

The following applies to surface finishes:

+ inner: sheet area Ra ≤ 0.8 μm and weld seam Ra ≤ 1.6 μm,

+ outer Ra ≤ 1.6 μm.

In the forming area – as in DIN 11852 – increased surface roughness by a factor of 2 is permitted.

Reworked weld seams must have a surface roughness of Ra ≤ 1.6 μm.

Hygiene classes like in the German standards do not exist in DIN EN 10374.

(October 2021)

2020: New edition of DIN 11865

The 2020 version of DIN 11865 replaces the edition published in February 2012. The preface of DIN 11865 lists the changes compared to the old version. We deem further information to be of interest to you. This supplementary information is therefore provided in order to clarify the new DIN 11865 standard:

- Chapter 3 "Terms" has been added.

- Chapter 4 "Symbols and Abbreviations" has been added.

- Chapter 5 "Ordering Information" has been added. In the edition from February 2012, the ordering information was included in the Chapter "Measurements, Designations" for the corresponding part type.

- Chapter 6 "Dimensions". The designation of the diameter nominal DN was changed to metric dimensions for reasons of uniformity with the ASME dimensions, e.g. DN ½ is now DN 12.7.

- Chapter 8 "Tolerances". Here, ranges have been defined for the parts in which the specified tolerances of a part dimension must be adhered to.

- Chapter 9 "Surfaces". In general, all weld seams must be ground on the inside and outside. If a manufacturer does not wish to do this, it must specify the option "u" (circumferential nozzle weld seam, not ground) in accordance with the ordering information in Chapter 5.2. If no details are specified, the weld seams must be ground on the inside and outside.

(December 2017)

The NA 003-01-14-AA work committee "Fittings for the Food Industry" of the DIN Standards Committee (NAA) – in which LINNEMANN GmbH participates – has approved the following standards for publication by the DIN.

DIN 11853-1 Hygienic pipe screwed connections

DIN 11853-2 Hygienic flange connections

DIN 11853-3 Hygienic clamp connections

The DIN 11853 standard concerns hygiene class H2 and replaces the previous standard from April 2011.

DIN 11864-1 Aseptic pipe screwed connections

DIN 11864-2 Aseptic flange connections

DIN 11864-3 Aseptic clamp connections

The DIN 11864 standard concerns hygiene classes H3, H4 and H5 and replaces the previous standard from November 2008.

Here, we would like to report in extracts on the following point, which is described in all the standards listed above.

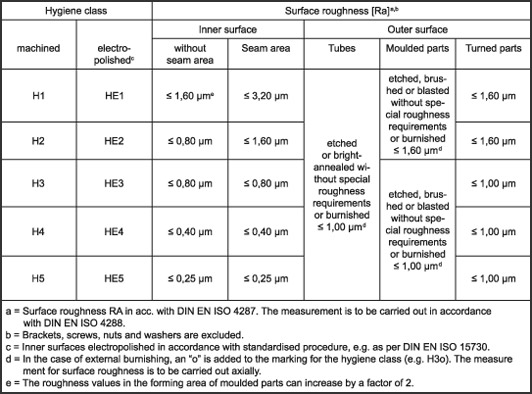

Inner and outer surface character

Compared to the previous standards, the table has been expanded and values adjusted.

The description of the articles has been expanded and made more precise in terms of roughness information. The table includes descriptions of related pipe components. As a result, the descriptions of surface requirements have also been standardised. The standard can be obtained from the Beuth Verlag publishing house.

With this information, the articles can now be described more precisely and requested more specifically.